Robot Crop Pickers Limit Loss of Farm Workers to Trump Wall

Robotic devices like lettuce thinners and grape-leaf pullers have replaced so many human hands on U.S. farms in recent years that many jobs now held by illegal workers may not exist by the time Donald Trump builds his promised wall.

For many American farmers, the automation push isn’t just about the President-elect’s goal to seal the border with Mexico, the traditional source of cheap migrant labor for the world’s largest agricultural exporter. There just aren’t enough crop pickers around as immigration slows, deportations rise and the prospects of congressional reform look remote.

That’s what prompted Steve Tennnes, a fruit and vegetable grower in Charlotte, Michigan, to buy a $138,000 machine that can collect up to three times as many apples per hour than workers who currently use ladders and buckets, and do so more safely. He will be able to harvest more with fewer workers, and the benefits will expand as he replants his orchard over the next decade to make it easier for the device to operate among the trees.

“The trade-off isn’t, do you want a machine or do you want workers,” Tennes, 39, said by telephone from his 120-acre farm, where he employs 72 workers and produces apples, peaches, blueberries, cherries, pumpkins and sweet corn. “It’s do you want to be in business or do you not want to be in business.”

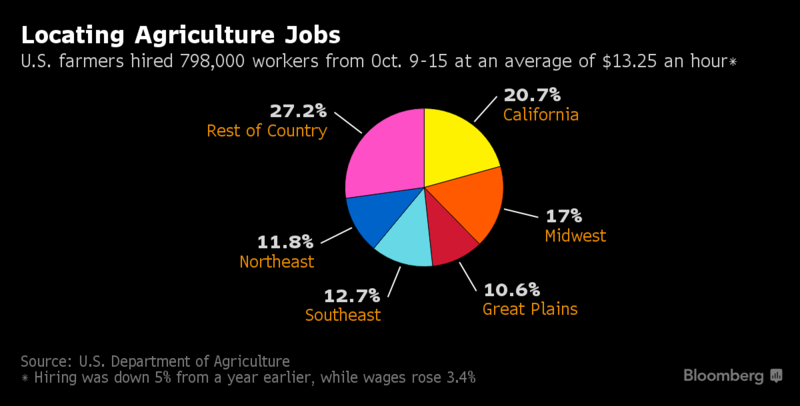

While seasonal hiring has slowed, average pay has increased. © Bloomberg |

After three straight years of declining U.S. farm income, sources of labor are becoming increasingly unreliable and costly, especially with illegal immigration likely to face a crackdown in the Trump administration. That’s forcing more growers to invest in machines that reduce human involvement in the production cycle.

More than 300,000 U.S. farm-workers don’t have valid immigration papers, according to a 2009 survey by the Pew Hispanic Center. Other studies suggest the number may be more than 1 million, based on the seasonality of the work and historical trends. That would be a sizable chunk of the more than 2.6 million jobs that the U.S. Department of Agriculture estimated for domestic farms last year.

Fewer Workers

But the supply of immigrant workers has been tightening. According to a Labor Department survey, in 1998, about 22 percent of foreign farm workers were in the U.S. for the first time. By 2013, that figure had plunged to 2 percent. Fewer are arriving illegally, and those who do come don’t want farm work, said Craig Regelbrugge, co-chairman of the Agriculture Coalition for Immigration Reform, a group of employers based in Washington.

The consequences are potentially dire, and could mean higher prices for some foods, according to a 2014 study from the American Farm Bureau Federation. An immigration policy focused on closing the border would shift up to 61 percent of fruit production to other countries, sending jobs to Mexico and other nearby competitors, according the the biggest U.S. farmer group.

The government should create a new agricultural guest-worker program and streamline an immigration bureaucracy that currently keeps legal workers from entering the U.S., said Kristi Boswell, a Farm Bureau lobbyist.

“We support border security,” Boswell said. “We will be looking for opportunities to use the enforcement pieces to make sure that agriculture has access to a new program.”

Compared to any other region or state, California has the most agriculture jobs. © Bloomberg |

In the meantime, the prospect of tougher restrictions is ginning up more interest in machines from farmers who previously shied away from such big investments, according to Tony Koselka, the co-founder of Vision Robotics Corp. in San Diego. The company sells lettuce-thinning machines for as much as $430,000 that reduce the need for hand-picking of the perishable crop.

The vineyards in Lodi, California, owned by Brad Goehring are adding mechanical leaf-pullers to the automated harvesters that already reduced his need for migrant grape-pickers by 95 percent. While his non-harvest workforce remained stable, he now needs just 15 people to pick the grapes, down from 300 before the machines.

‘De-Incentivizing Labor’

“The machine shows up to work every day,” said Goehring, 52, a fourth-generation farmer who started mechanizing in 2008. “The government is de-incentivizing ourselves from having labor,” said Goehring, a one-time Republican congressional candidate who said he voted for Trump for his pro-business views.

Machinery manufacturers are likely to keep focusing on reducing costs for robotics and automation, according to a report from Boston-based Lux Research Inc., written by Sara Olson and Laura Lee. For example, Case IH, the agricultural-machinery unit of CNH Industrial NV, last year unveiled a concept for an autonomous tractor.

While the slow march of mechanization is hardly new in the U.S. -- where John Deere’s steel plow revolutionized Midwest farming almost two centuries ago and helped give birth to a global agricultural powerhouse -- many innovations have been tied to stricter immigration policies.

Mechanical tomato-pickers began showing up in California in the late 1960s, after the end of a program that allowed temporary Mexican harvest workers into the U.S. In American dairies, which operate year-round and struggle to find workers under the government’s six-month H-2A farmworker visas, farmers have been shifting to robots that do everything from milking to feeding to cleaning the cows.

By Hand

Even with all the technological advances, there are many crops that still require human hands, at least for now, said Wallace Huffman, an agricultural economist with Iowa State University in Ames. Machines typically work better for foods grown for processing rather than those sold in grocery stories, because many consumers demand an unblemished appearance, he said.

“The soft fruits, the berries, the strawberries and blueberries are very delicate,” Huffman said. “They can easily be bruised and smashed, even by hand. Trying to move to mechanical picking is difficult.”

Still, with new devices being developed and Trump’s push to limit illegal immigration, the industry is accelerating its shift to automation.

“Labor shortages are the main driver of the economics of what we’re doing,” said Charles Grinnell, the chief executive officer of Harvest Automation Inc. in Billerica, Massachusetts, which produces robots for $32,000 apiece designed to harvest plants in greenhouses. “It’s hard to know if it’s the election of Trump or something else. But there really is a sense from our customers that, ‘Hey, let’s get this done.’ ”