Packinghouse automation dazzles and more is on the way

When you look at the packinghouses of yesteryear, you see a glimpse into a world that doesn’t exist today.

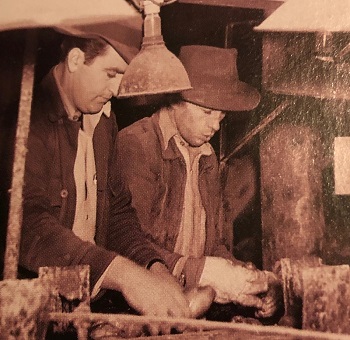

In The Packer’s 1993 Century of Produce, there are numerous photos from the “early days” of modern produce distribution. In a photo of potatoes being sorted in an Idaho packing shed in the 1940s, 30- something-year-old men with hats and jackets were side, by side, with gloved or ungloved hands all over the potatoes coming down the line.

Source: The Packer's Century of Produce

Another shot of Sunkist packers from the 1920s shows a big collection of men, most wearing hats and some sporting aprons and bow ties, pausing for a photographer’s shot by wooden crates they were filling with oranges.

Seeing those shots reminds me of how far the industry has come in terms of packinghouse innovations. Today, there are far fewer folks in the packinghouse, and nearly all of them are women.

Now, we see an epic scale to packinghouses never dreamed of a century ago. Inside, we see all kinds of automation in the movement of fruit through the facility. “Computerized sorting machines” and “robotic palletizers” are insufficient terms to describe the level of innovation taking place.

For example, Wonderful Citrus has said on its website that the company’s packinghouse for Halo mandarins can handle an astounding 4,000 bins of fruit daily.

Given the severe difficulty in finding labor for packinghouse positions, even more automation is needed in coming years.

I posed this question to the LinkedIn Fresh Produce Industry Discussion Group: What have been the biggest packinghouse technology innovations in the past 25 years? Is the lack/shortage of labor the "mother of invention" for packinghouse innovations? Responses here will help me with an upcoming section for The Packer, so your insights and observations would be helpful. Also, what will the next wave of packinghouse innovations look like? #innovation #packing #sorting #robotics

John Pandol has been active on this thread so far, and has brought up numerous advances:

- The grading and sorting side has lots of mechanization, but the packing less. Gravity-fill clams and bags, maybe some sealing technologies. I think soft-hands technologies driven by optical intelligence will expand the items that can be packed (and harvested ) by machine.

- Onion hyperspectral imagery that detects decay several layers down into the onion.

- Blueberry and cherry lines that take 56 photos, including with air jets to see if the fruit is too soft. Air jet and photo simultaneous and, if the skin gives, another air jet kicks it out.

- Over the past 30 years, the machinery to manufacture baby carrots out of whole pieces.

- The development of machinery to separate pomegranate arils from the skin and pith, for both fresh and juice applications

I would love to hear from providers of sorting/palletizing/packing technology what may be around the corner. What is the most efficient fresh produce packing operation today, in terms of cartons packed versus labor required? Is the packinghouse the best bet for continued investment in automation? How is automation entering into produce distribution at wholesalers and retail distribution centers?